top of page

LED Measuring Cup

Project Length

5 weeks

Problem Statement :

The LED Measuring Cup is designed to Enhance Precision in Cooking for Any User.

Skills Used :

Research, Sketching, Fushion360, Prototyping, Keyshot

problem statement : common measuring cups

"I encounter difficulties reading the measurements on the side of the cup, as the lettering is too small."

"I experience back strain from frequently bending down to accurately read the water level on the side of the cup."

"I find it challenging to securely grasp the cup's handle because the handle due to its lack of defined edges."

anatomy of a liquid measuring cup

LIP

HANDLE

MEASUREMENTS

BRAND IDENTITY

GLASS SIDES

task analysis : a step-by-step study

pain points

Measurements Are Difficult To Read And View

Lip Has Issues When Pouring

Hand Grip Causes Discomfort During Usage

problem statement

To Design a LED Measuring Cup that Enhances Precision in Cooking by incorporating Coded Sensors for Any User.

design goals

INCREASE PRECISION

Insuring that the cup's measurement is correct and accurate.

LED SENSING

Achieving an integrated LED system to read measurements based off of water level sensor.

ERGONOMICS

Improving form and functionality with integrated electric components.

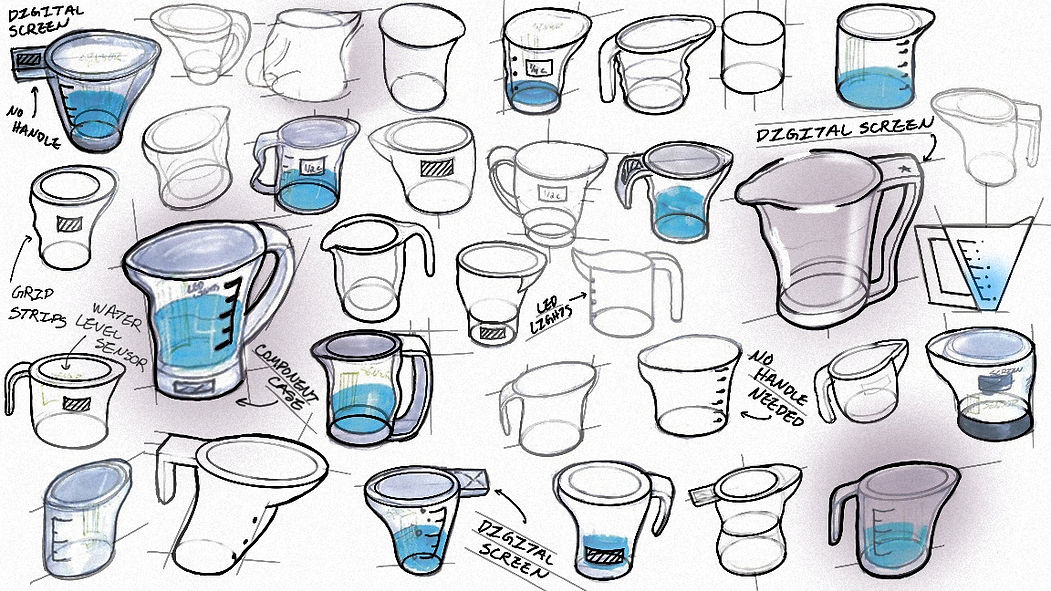

sketches : ideation level sketching

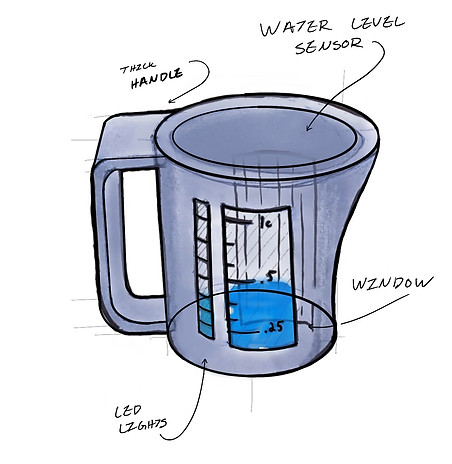

sketches : second level sketching

sensor analysis

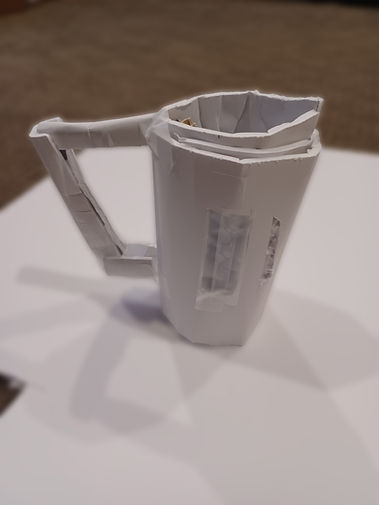

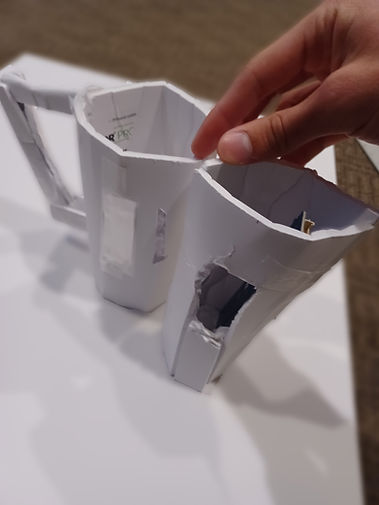

foam board prototype

Handle should be attached to the cup.

"Using two cups to house the components is an excellent idea!"

cad model : each measurement on the cup is correlated to the taper angle to perform the correct size of liquid.

1/1

3D printed forms

final model

A clear window designed to see water pour into the cup.

The blue LED light simplifies water.

water level sensor

The numbers on the side represent how many cups of water are in the cup.

exploded view with materiality

Components

1. Grove Water Level Sensor

2. LED Light Strip

3. Nano Arduino Board

4. Mini Breadboard

5. Wires (7)

6. Glass

7. Black Plastic

renderings : lip

LED light and handle

final render

bottom of page